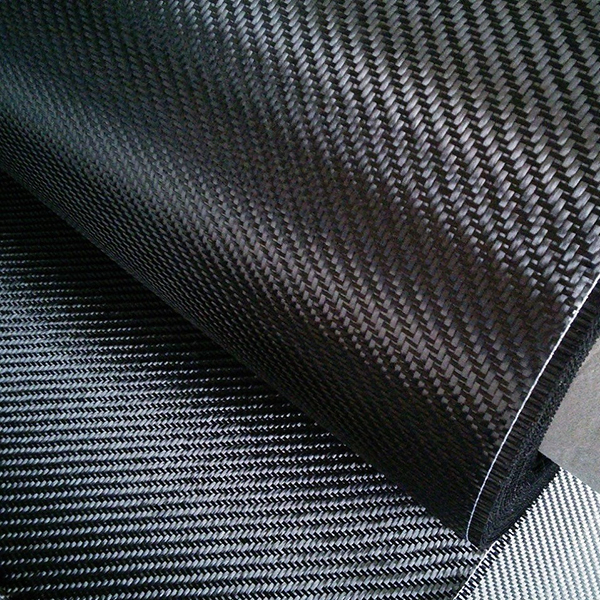

Cov ntaub iav fiber ntauyog ua los ntawm iav kheej kheej lossis iav pov tseg los ntawm kub melting, kos duab, winding, weaving thiab lwm yam txheej txheem, nws txoj kab uas hla ntawm monofilament yog ob peb microns mus rau 20 microns. Sib npaug rau 1/20-1/5 ntawm tib neeg cov plaub hau, txhua pob ntawm fibrous precursors muaj ntau pua lossis ntau txhiab tus monofilaments.

Dab tsi yog cov yam ntxwv ntawm cov ntaub fiberglass?

1. Rau qhov kub thiab txias -196 ℃, siab kub 300 ℃, nrog huab cua tsis kam;

2. Tsis-nplaum, tsis yooj yim rau adhering rau tej yam khoom;

3. Corrosion tsis kam rau tshuaj corrosion, muaj zog acid, muaj zog alkali, aqua regia thiab ntau yam organic solvents;

4. Tsis tshua muaj kev sib txhuam coefficient, yog qhov kev xaiv zoo tshaj plaws ntawm cov roj-dawb tus kheej lubrication;

5. Kev xa tawm yog 6≤ 13%;

6. Kev ua haujlwm siab rwb thaiv tsev, tiv thaiv UV thiab hluav taws xob zoo li qub.

7. Lub zog muaj zog, nrog cov khoom siv zoo.

Ib tug neeg nug seb qhov haujlwm ntawm fiberglass daim ntaub yog dab tsi? Nws zoo li lub tsev ntawm cov cement thiab hlau. Kev ua haujlwm ntawm cov iav fiber ntau yog zoo li cov hlau bar, uas ua lub luag haujlwm ntxiv dag zog rau cov iav fiber ntau.

Nyob rau hauv dab tsi teb yog fiberglass ntaub siv?

Fiberglass daim ntaub yog tsuas yog siv rau phau ntawv pulp molding. Cov iav fiber ntau cov ntaub ntawv square ntaub yog tsuas yog siv rau lub cev, lub tank, txias yees, nkoj, tsheb, tso tsheb hlau luam, cov ntaub ntawv hauv tsev, iav fiber ntau yog siv rau kev rwb thaiv tsev kub, tiv thaiv hluav taws, nplaim taws thiab lwm yam kev lag luam. Cov khoom siv absorbs cua sov ntau thaum nws kub hnyiab, tiv thaiv cov nplaim taws thiab cais cov huab cua.

Dab tsi yog qhov txawv ntawm daim ntaub fiberglass thiab iav khoom?

Cov khoom tseem ceeb ntawm iav fiber ntau daim ntaub thiab iav tsis sib txawv heev, feem ntau yog los ntawm kev tsim cov khoom siv sib txawv. Fiberglass daim ntaub yog ib qho zoo heev iav filament ua los ntawm iav, thiab cov iav filament muaj softness zoo heev nyob rau lub sij hawm no. Cov iav filament yog spun rau hauv xov paj, thiab tom qab ntawd cov ntaub fiberglass tuaj yeem woven ntawm ib lub loom. Vim hais tias cov iav filament yog li nyias, qhov saum npoo ntawm ib chav tsev loj heev, yog li qhov kev tiv thaiv raug txo. Nws zoo li melting ib daim nyias ntawm tooj liab nrog ib tug tswm ciab, tab sis lub iav tsis hlawv.

Yog hais tias lub cev yog glued rau cov iav fiber ntau, daim tawv nqaij yuav khaus thiab tsis haum, tab sis feem ntau yuav tsis muaj kev raug mob hnyav, noj ib co tshuaj tiv thaiv tsis haum yuav zoo.

Post lub sij hawm: Nov-08-2022